| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

WHAT IS THE CUSTOM CONTAINER HOUSE

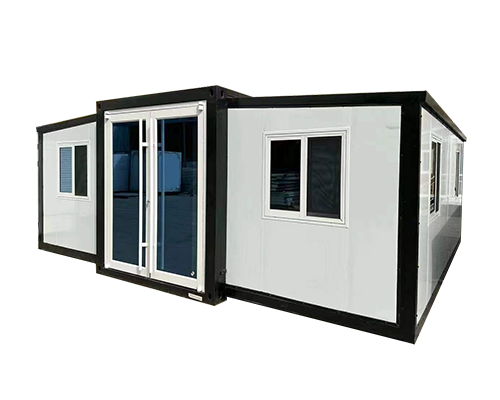

Custom add-on container is collapsible container room which can be manually opened at location, out of one unit to three units. It can be made according to needs.

CUSTOM CONTAINER HOUSE STRUCTURE

27-72 ㎡ super big room, 12 wind finiteness, 9 earthquake resilience, 20ft units can be stacked into 2 layers, other sizes can only be stacked into 1 layer, can open and close 120 times, the height is flexible and adjustable according to your needs.

Step 1:Clarify Material Access Standards (Source Control)

Create a 'qualification review + sampling re-inspection' system. Set by number for main items such as Q355B steel (yield strength≥355MPa), EPS heat-insulating stuff (thermal transfer coefficient≤0.042W/(m·K)), and door locks (break strength≥1000N) for reliable source quality.

Step 2:Steel Cutting and Blanking

Adopt CNC plasma cutting. Make sure the size change is not more than one millimeter, the cut edge is not more than zero point five mm/m out of upright and there are no burrs and no corners are left out. Do a total check on how the cut edges appear.

Step 3:Frame Welding

90.Adopt CO₂ gas shielded welding (120-180A, 20-25V). Make the weld height ≥ 6mm and no faults. Conduct 100% ultrasonic flaw detection for all main frame welds. Rework unqualified welds and inspect again.

Step 4:Frame Straightening and Forming

The reduced brucite sample was straightened, the horizontal deviation was ≤ 3mm, the column perpendicularity was ≤ 2mm/m, and the bent beam flatness was ≤ 1mm/m. Conducted 100% inspection and magnetic particle test on the key parts to not find cracks or deformity.

Step 5:Enclosure System Installation (Core of Thermal Insulation and Waterproofing)

Use 1.8mm magnesium oxide boards as the base with weld spacing ≤ 200mm and Avoid hollowing. Splicing gap of EPS thermal insulation boards≤ 2mm. The overlap of outside wall color steel plates≥ 100mm, the roof slope≥ 5°, 24 hr water tightness test must conduct to prevent leak.

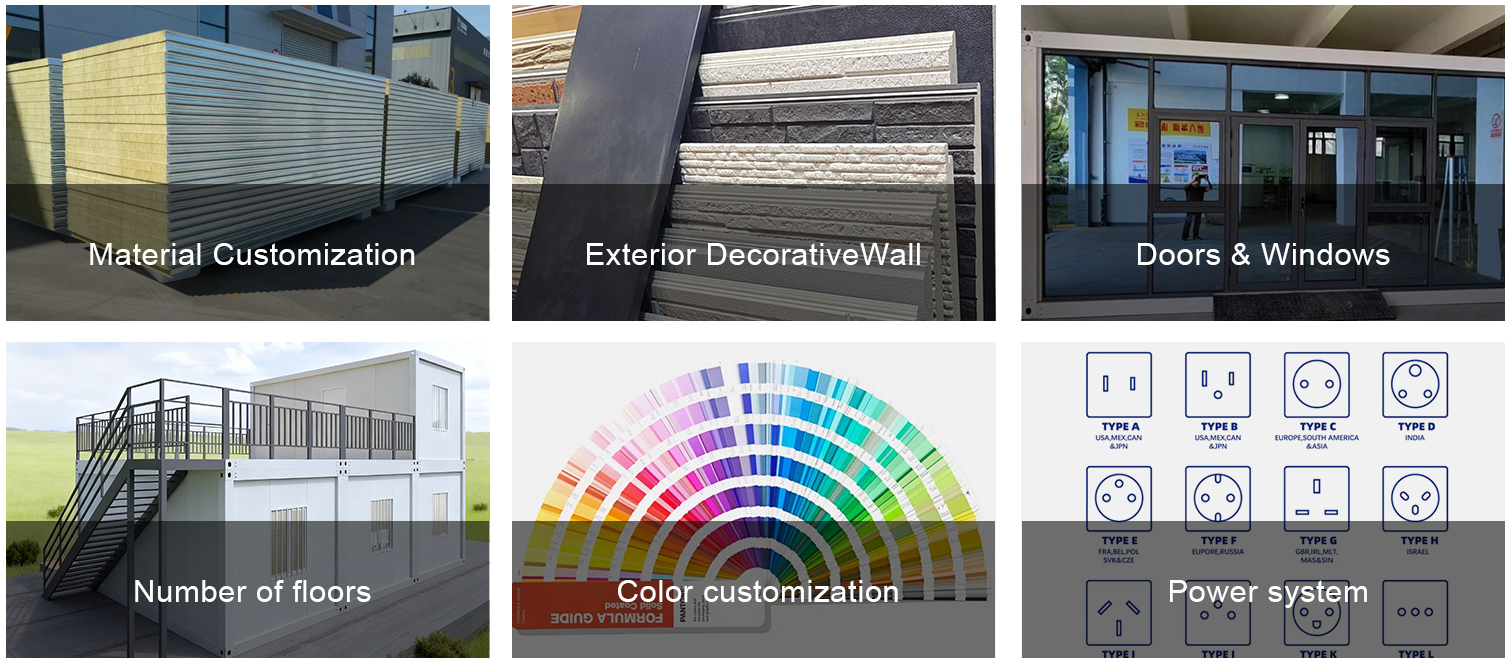

Step 6:Supporting System Installation (Doors, Windows, Water and Electricity)

Make sure the door and window airtightness is up to standard (air leakage ≤ 0.1m³/(h·㎡) under 0.5kPa). Use the tempered glass with the thickness is no less than 5mm. Use BV copper core wires and PPR pipes for water and electricity system. Do a water pressure test with the pressure of 0.8MPa for 30min, and the pressure drop shall not be more than 0.05MPa. The power-on test shall have 100% pass rate.

Step 7:Factory Acceptance and Filing (Inspection Closure)

Implement the three-inspection system (self-inspection, mutual inspection, special inspection). Attach labels to qualified cabins and take photos for record-keeping. Isolate and rework unqualified products. Keep all records for more than 3 years.

Step 8:Delivery Acceptance Coordination

Conduct the three-inspection system (self, mutual, special). Stick tags to the cabins that are qualified and take photos for record. For unqualified goods, put some space between and rework. Keep Record for more than 3 years.

Step 9:Quality Tracking and Feedback

Make unique quality files and follow up as per the “1-month return visit, 3-month check, 1-year restore" plan. Get back to customers within 48 hours and fix issues within 72 hours. Come if needed within 24 hours.

Cammi House has the world's biggest production base for capsule and container houses. It is also home to a 90,000-square-meter top-notch manufacturing center with fully-automated lines. As the world's biggest manufacturing hub for capsule and container dwellings, we use megomachineolgy and lean sys to produce the highest quality at an almost full-out ability. With our act owned notch, we professional and wholesome international leaders in our field. |

| ✔ Flexible Delivery Time | ✔ Low MOQ | ✔ Exclusive Regional Rights & Pricing Support |

| Reliable delivery schedules and warehousing support | Flexible MOQ with mixed product options | Brand Authorization Ensures a Competitive Edge in the Market |

| ✔ High Cost-Effectiveness | ✔ Custom Logo | ✔ R&D Resources |

Competitive pricing to maximize overall value. | Personalized Logo Customization for Small Batches | Provide 3D Sample Images and Floor Plans Within 7 Days |

| ✔ Wide Product Selection | ✔ One-Stop Marketing Package | ✔ 15 Days Fast Delivery |

| Diverse Options to Cater to All Market Segments | Provide Quality Images, Videos to Enhance Sales Revenue | Efficient Production and Ship Within 15 Days at the Fastest. |

Products undergo several certifications and tests; like CE FCC ETL.IS0 9001.

and Eneray Star on yearly basis, based on clients' wants to confirm conformity with the global safety, quality and efficiency standards.

130+

Certifed Patent

Each tech should have patent protection so there will be legal safety and no competitor can come in.

3000+

Project Cases

Honed through more than 3000 projcts, strength has shaped an energy use in container living.

10%

New R&D Expenses

One-tenth of the gains are put to work closed in the steady better works.

100+

Technical Team

Technical team in full, one is sure of both quality and service.

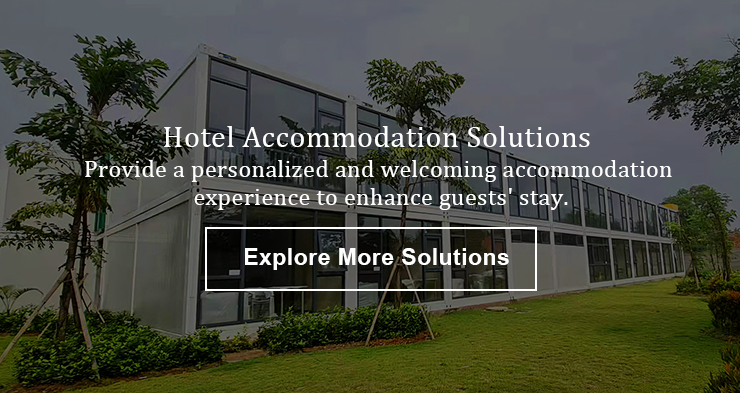

Commercial Use

Motel& Resort

Mining Camp

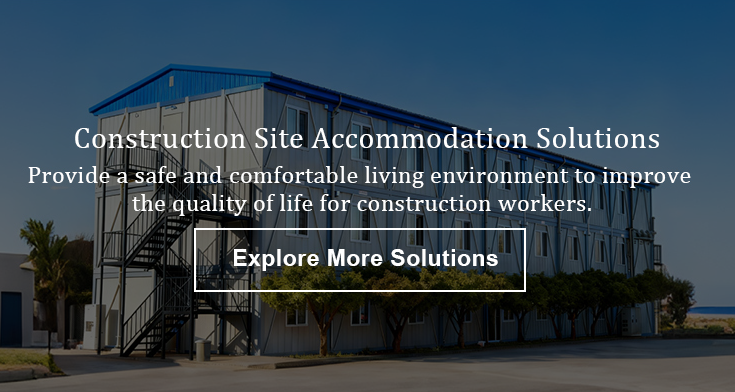

Construction Camp

Cammi was very good to us by giving us the best camps, huge steel smenst Factress, the furniture and camps gears and we used for our speed capsule project in the US. We have very happy and excited about what, and how they did and will work with them, again, on jobs coming soon!

Cammi is our dependable provider for the Space Capsule Thailand project. We have been working with them for three consecutive projects. I love their warm and skilled members of staff! I highly recommend Cammito to anyone wanting to buy good prefab homes.

Cammi made our space pod Rhan l and Bay. She planned it, made it and watched over it. The work all fit in our low budget and was done fast. We have run the space pod for two years. We like the anti-corrosion drain system very much. We are very happy with the work on the container.

Q: What kinds of products can you offer?

A: Our product is a range of residences like the prefabricated K house and the prefabricated T house, villas, mobile containers, light steel structures, guards and others.

Q: What are your house materials?

A: The main stel structures are square tube,"c" section stel,"H" section stel, angle steel. The walland roof materials are waterpro EPS panel; fireprof frock wol panel; Welinsulated PU panel; Strong concrete panel, These materials can be used for more than 30 years.

Q: Are you the factory or the trading company ?

A: Certainly, we are a factory and we can offer you a good price.

Q: Did you have the experience to cooperate with the government?

A: Well,we have many experiencesto cooperate with the government. We have cooperated with the Maldives Government,Inda Government,lndonesia Government,East TimolGovernment, Philippines Government, Pakistan Government and so on.

Q: How is your after-sales service?

A:

1. any question, can contact us freely.24 hours anytime for your service.

2. One order, one especial person to follow all the process.

3. For the house instalation, will send you the3d install drawing in time. If you need, can also send you a enginer to teach your workers. But you should pay for him back ticket and return hotel, food and salary.

Q: What information should we offer before you quote ?

A: Once you have the drawing, please deliver us and say us the material that you use.Answer, you do not have the drawing, tell us the house size. Next, we shape for you at a good rate, Have any Question, do not hesitate to talk with us !!

Internet-famous Box

Double-opening Z case

Expansion Box

Packing Box

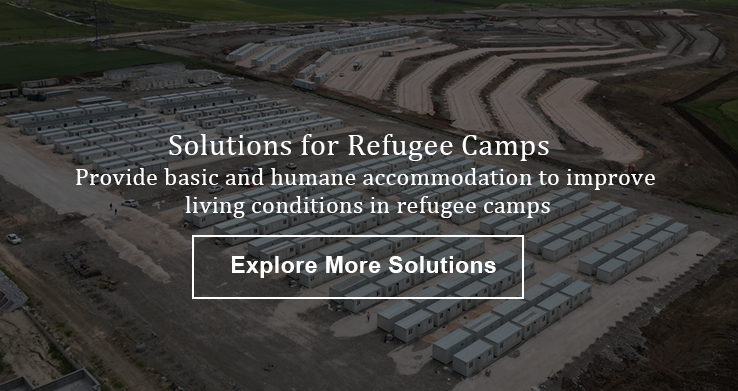

Mesaieed Industrial City 10,000-Man Workers Camp

August 1,2025/ August 20.2025

Cammi ran life support camp for 10,000-capacity plant and liquid/oil storage at Qatalum to work for.

November 18,2025/ November 25.2025

Any ready and cutting Cammi finished the job on 26,000 work men city project.

Mobile Medical Hospital and First AidStations

December 1,2025/ December 3.2025

British residents can enjoy Cammi's health clinics in just 120 minutes as they have been made readily accessible through extensive research and development.

Product Highlights 1. Prefab Container Homes – High quality, made in a plant by consistent rules. 2. Packable Container Home System – Smaller packed for easy move, fast build. 3. Made to fit Container House Forms & Finishes – Can handle almost all project musts. 4. Container Homes Storage Ready – Can be to live in, to hold stuff, and use again.

Product Highlights 1. Custom Container House Design – Layouts and finishes adapted to your needs. 2. Expandable Container House Structure – Grows on site to add room for living. 3. Modern Container Homes Style – Clean lines with an up-to-date look. 4. Fast Prefab Installation – Cuts number of hours and worker pay.

Product Highlights 1. Container Custom Homes - Custom arrangements for stock or odd jobs. 2. Folding Container House Design - Collapsible frame for ease of carry and fast assemble. 3. Storage Container Houses Solution - Safe, practical and space saving. 4. Durable Steel Structure - Created for perform repeat and long years of service.