| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

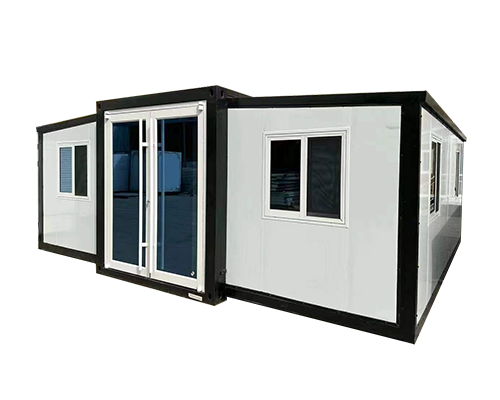

WHAT IS THE EXPANDABLE CONTAINER HOUSE

The expandable container is a mobileroom container that can be depolyed manually on site by folding it out, changing one into three.

EXPANDABLE CONTAINER HOUSE STRUCTURE

27-72 square meters of extra-large space, 12 levels of wind resistance, nine levels of earthquake resistance, 20 feet that can be stacked up to twice the amount. others can only be stacked one time; can open and shutdown 120 times. very mobile, best choices are one bedroom with living room and a kitchen and a bathroom; two bedrooms with living room and a kitchen and a bathroom; three bedrooms with living room and a kitchen and a bathroom.

|  | ||

Small 20FT: Installed size:5900L*4800w*2480(H)mm Interior size: 5460L*4640W*2480(H)mm Folded size:5900L*700W*2480(H)mm Area: 27.5㎡ 40HQ=6 units | 20FT: Installed size: 5900L*6320W*2480(H)mm Folded size: 5900L*2200w*2480(H) mmArea:38㎡ 40HQ=2 units | ||

|  | ||

30FT: Installed size: 9000L*6240W*2480(H)mm Folded size: 9000L*2200W*2480(H)mm Area:54㎡ 40HQ=1 units | 40FT: Installed size: 11800L*6240W*2480(H)mm Folded size:11800L*2200W*2480(H)mm Area:72㎡ 40HQ=1 units | ||

Step 1:Clarify Material Access Standards (Source Control)

Create a "review of qualification + rechecking sample" process. Give no more than a certain amount for key parts like Q355B steel (5700psi), EPS thermal heat saver (leakair 0.042W/(m-m).K)), and door lock (brings hold hold 13500N) to keep starting quality under control.

Step 2:Steel Cutting and Blanking

Adopt CNC plasma cutting. The deviation of size should be ≤ ±1mm, the right angle of the cut should be ≤ 0.5mm/m , and burrs or missed corners should not occur. Make a 100% appearance check for the cut edge.

Step 3:Frame Welding

Follow CO2 gas shielded arc welding (present: 120-180A, 20-25V). Keep the weld height: 6mm or higher; avoid cracks and deformations. Conduct ultrasonic flaw detection for all the welds of mainframe; rework the unqualified welds and make re-inspection.

Step 4:Frame Straightening and Forming

After that, the oblique shift should be less than or equal to 3mm,column vertical run out less than or equal to 2mm/m and the beam flatness less than or equal to 1mm/m. carry out 100 Volunteer visa examination and magnetic particle examination on key parts to make sure there is no crack and deformed.

Step 5:Enclosure System Installation (Core of Thermal Insulation and Waterproofing)

Use 1.8mm magnesium oxide boards for the floor with weld spacing ≤ 200mm and no hollowing. Make sure the splicing gap of EPS thermal insula-tion boards ≤ 2mm. The cut-off of outside wall color steel plates ≥ 100mm, the roof slop ≥ 5°, and do 24-hrs water tightness test to avoid leak.

Step 6:Supporting System Installation (Doors, Windows, Water and Electricity)

Ensureness of door and window prevents leaked air ( 0.5kPa air leakage ≤ 0.1m³/(h· ㎡)). Use toughened glass of own 5mm. Use BV wire and ,master pipes in water and electricity system. Use water pressure of 0.8 MPa for 30 min, as as pressure failure of 0.05 MPa., Pass rate for terminating powered on.

Step 7:Factory Acceptance and Filing (Inspection Closure)

Follow the three-inspection system (self-inspection, mutual inspection, special inspection). Place labels on qualified cabins and take photos for record-keeping. Remove unqualified products and repeat the work. Keep all records for more than 3 years.

Step 8:Delivery Acceptance Coordination

Customers will be with our QC people for acceptance, and they will sign the confirmation form if not objected. If there is a problem, the corrective plan shall be put within 24 hours and re-inspection shall be carried out after correction.

Step 9:Quality Tracking and Feedback

Create good files and follow the content of the plan of "one month regimen, three months check, and 1 year maintain" only. Face customer problems within 48 hours and solve within 72 hours. In case of emergency go to the place within 24 hours.

Cammi House has a modern 90, 000-squaremeter making plant with fully automated production lines . It is the largest production plant for container and capsule homes in the world, and we use advanced technology and similar systems in the whole process to ensure high quality products, while working quickly. Our focus on quality makes us the leader in the market. We also work on new ideas and work on green ways to build simple buildings. |

| ✔ Flexible Delivery Time | ✔ Low MOQ | ✔ Exclusive Regional Rights & Pricing Support |

| Realistic timelines for sending and putting away stock | Flexible MOQ varied product choices | Brand Authorization Certifies a Steady Presence in the Market |

| ✔ High Cost-Effectiveness | ✔ Custom Logo | ✔ R&D Resources |

Competitive prices to get the most out of your money. | Customized Logo Personalization for Tiny Sets | Give us 3 D sample pics and plans of Suahfart within a week |

| ✔ Wide Product Selection | ✔ One-Stop Marketing Package | ✔ 15 Days Fast Delivery |

| Different Plans to Meet Every Part of the Market | Provide Quality Images, Videos to Increase Sales Risese | The fastest way to produce well and ship it in 15 days. |

The products are tested and certified many times throughout their use. For each use, the product has to pass the following standards: CE, FCC, ETL, ISO 9001, and Energy Star. Since the products meet all the applicable international safety, quality, and performance standards, they are safe.

130+

Certifed Patent

Think of owning each process so that they can't be used by others unless you allow it.

3000+

Project Cases

Efficiency in container housing has been created by strength through over 3,000 projects.

10%

New R&D Expenses

Each year, ten per cent of profits go towards ever better making of what we see.

100+

Technical Team

Guarantee both quality and service with a full technical team.

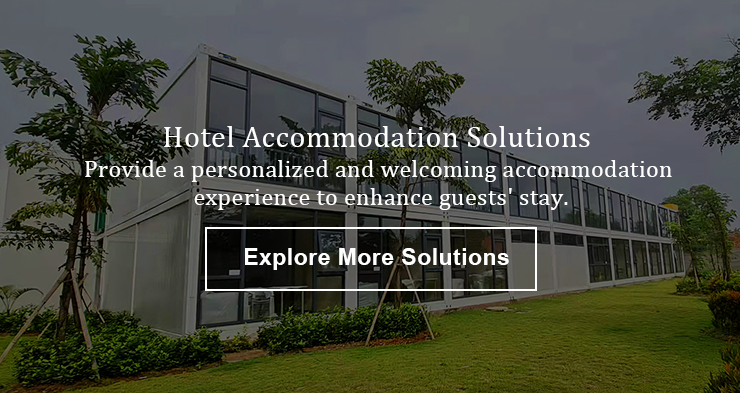

Commercial Use

Motel& Resort

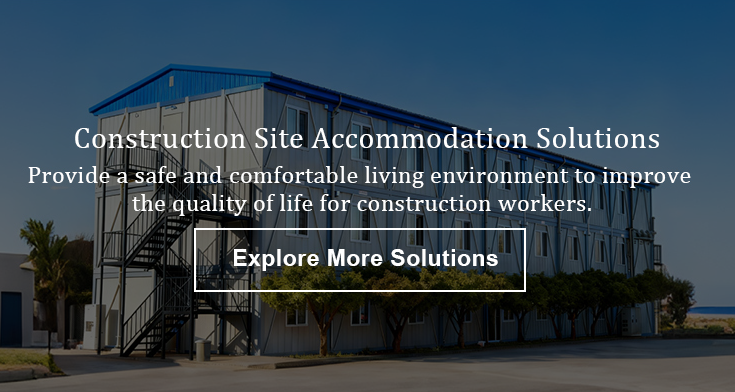

Mining Camp

Construction Camp

Many thanks to Cammi for giving us great camp factors to do with all the things we made from thin steel, including factories, tables, and stuff for our camp in the US. We are happy with what they made for us and can't wait to work with them on other projects!

Cammi is a good source for us in the Space Capsule Thailand project. We have dated three times. I loved their friendly and their real estate business team! I highly recommend Cammit to buy with them affordable prefabricated houses.

Our space pod project in Rheinl and Bay was designed, built and overseen by Cammi. From start to finish, the entire space pod was within our tight budget and on schedule. Our space pod has been in use for two years. The anti corrosion drainage system is top notch. We are happy with the quality of the container.

Q: What kinds of products can you offer?

A: We have a bunch of houses, like prefabricated K house, prefabricated T houses, vila, movable containers, light steel struct buildings, guard etc.

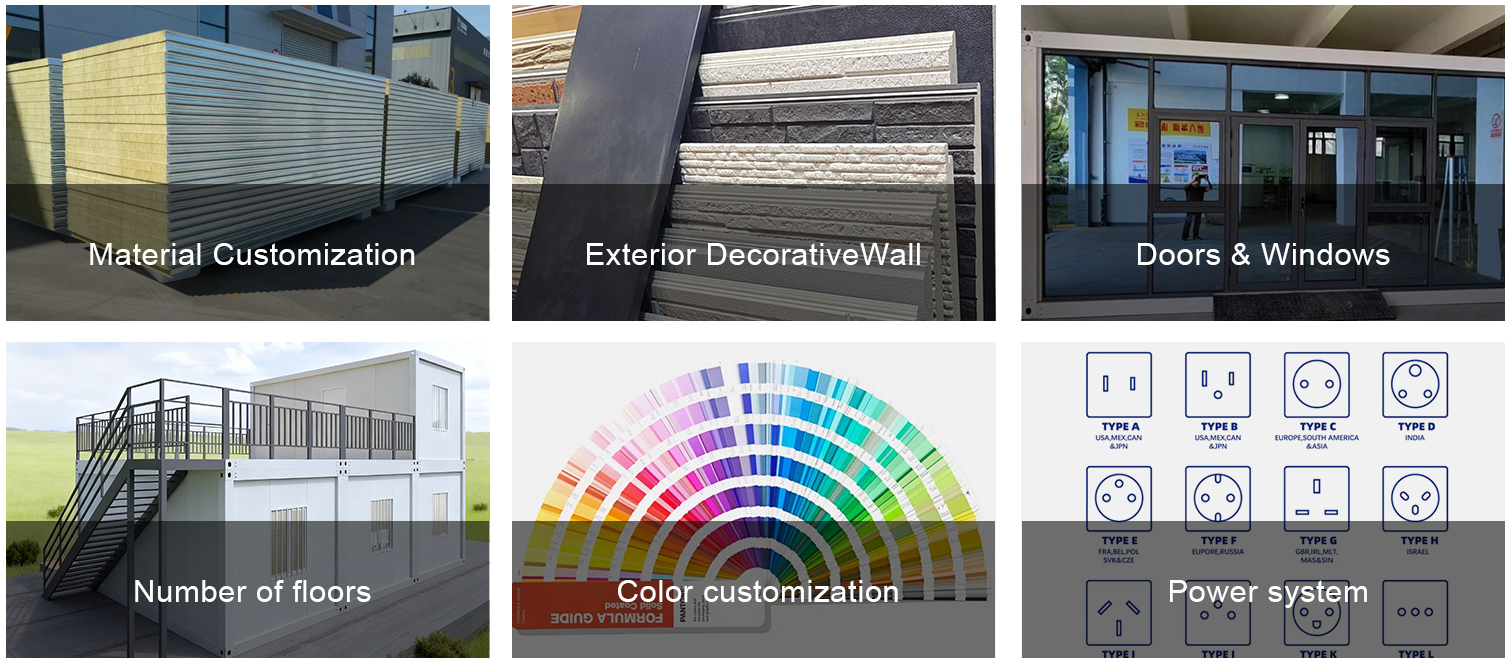

Q: What are your house materials?

A: The main stel structures are square tube, "c" section stel, "H" section stel, angle steel. The walland roof materials are waterpro EPS panel; fireprof frock wol panel; Welinsulated PU panel; Strong concrete panel, These materials can be used for more than 30 years.

Q: Are you the factory or the trading company ?

A: Absolutely, we are a shop and we can give you an affordable deal.

Q: Did you have the experience to cooperate with the government?

A: Yes,we have many experients to work with the government. We have worked with Maldivo Government, India. Government,Indonesia Government,East Timor Government, Philippinesis.Gornment, Pakistan Government and so on.

Q: How is your after-sales service?

A:

1. Any questions,welcome to contact us. 24 hours are at your choice.

2. One order, one special wanted to follow the whole product.

3. For the house install, we will provide your 3D install drawing. if you want, we can send an engineer to teach your workers, but you have to pay his return ticket, room, food and his wage.

Q: What information should we offer before you quote ?

A:If you have the drawing kindly give and tell us the material you use.In case you don't have the drawing tell us the size of the house.And after that we will make the design for you at a good price.Have any question don't to contact us!!

Internet-famous Box

Double-opening Z case

Expansion Box

Packing Box

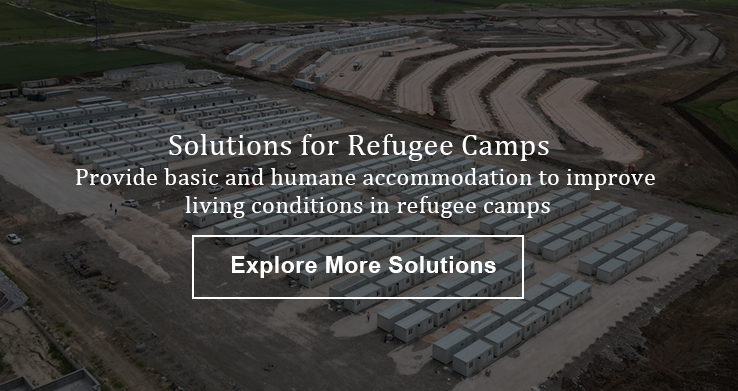

Mesaieed Industrial City 10,000-Man Workers Camp

August 1,2025/ August 20.2025

Cammi put up a life support camp with 10,000 beds for the workers and bosses at Qatalum's gas plant, cargo hold and storage plants.

November 18,2025/ November 25.2025

Cammi finished the city of 26,000 workers' housing in a comprehensive way.

Mobile Medical Hospital and First AidStations

December 1,2025/ December 3.2025

Released after thorough R&D studies, cammi’s mobile field hospitals are ready to use within 2 hours.

Product Highlights 1. Portable unit House Style - has more space to get in on site. 2. Mobile expandable Prefab Home - Portable house can be taken anywhere. 3. Factory Developed Expandable Shipping Container Home – Built and shipped from the factory. 4. Fast set up – Prefabs cut down on set up time and labor.

Product Highlights 1. Outdoor Prefab House Design – Ready for outdoor use using durable stuff. 2. Expandable Container Structure – Grows where you put it for more room. 3. 3 in 1 Expandable Container House – Small to move, big to use. 4. Container Storage Solution – Perfect to keep things secure and for many uses.

Product Highlights 1. Product Container House Design - Factory-made to give you better quality and last vlong. 2. 2 Bedroom Plan - Comfy area for people or workers. 3. Product Expandable Container House - Structure that can grow for more space. 4. Product Moveable Homes - Can be moved, shifted and used again quick.