| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

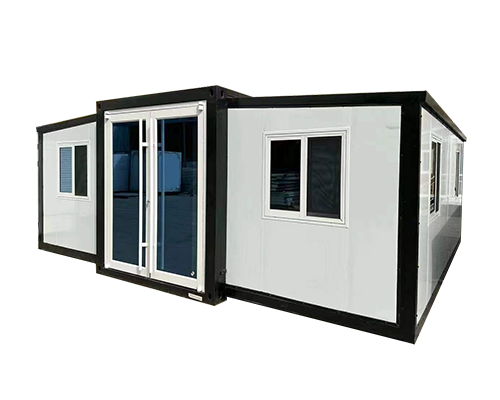

WHAT IS THE DETACHABLE CONTAINER HOUSE

Removable container homes are, of course, one of the check lives of covering, made by readiness nodes of the fabric remote at n a factory. They are then transferred to the order credibility where they beefy fit in to a load of fabric. They are cheap, not. b. can turn and not as annoying to make as this not. In these houses, of course, are designed to accelerate and rigid others, everlasting steel, filled to rough and gentle conditions, and TekScan, to match places all over the world, which, believe it or not, makes them a good fit for house building.

DETACHABLE CONTAINER HOUSE STRUCTURE

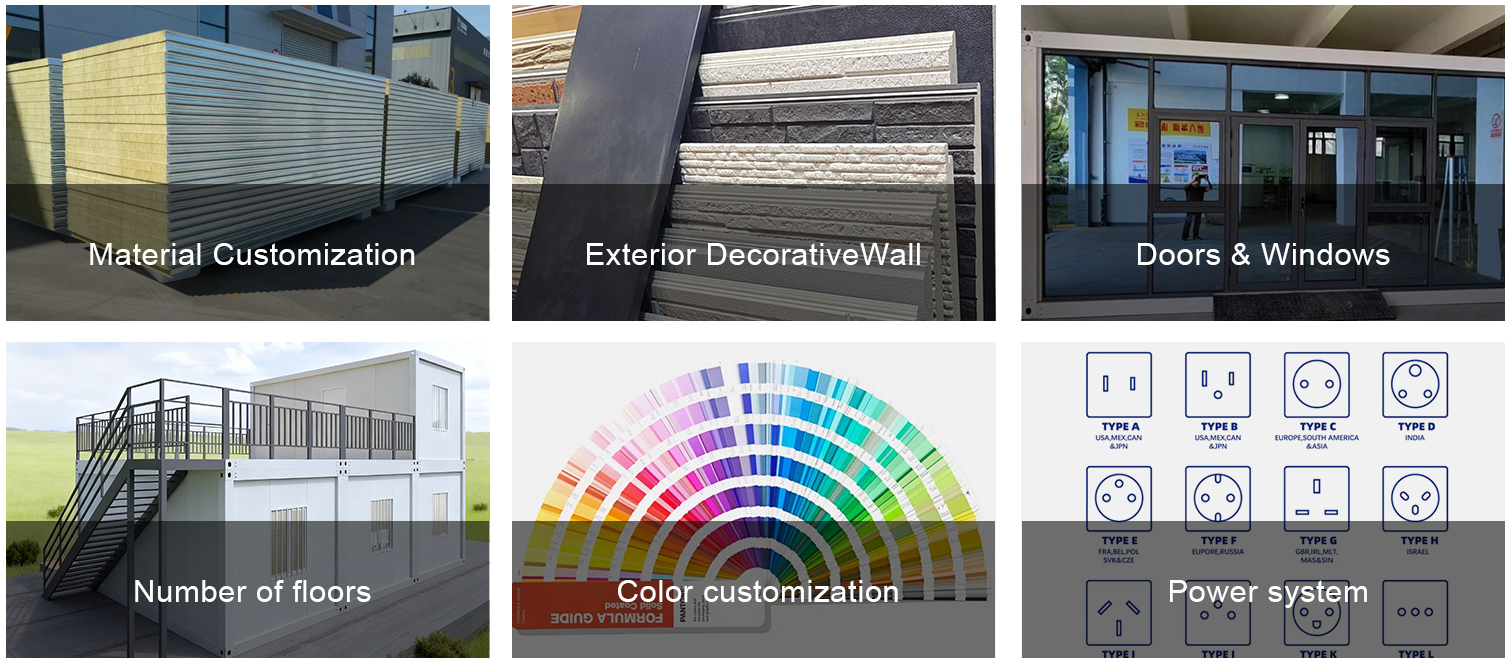

Normally, a container that is made of pre-built metal has measured 3*6 meters or 20ft, and has only a door, two windows and simple electrical/ lighting. Great versatility is the one that 20ft container house unit has. More attractive looking makes a 20ft container house unit depends on its size, its thickness of furniture and its shape of body. Yes, you can have whatever stuff you want in it. Also, you can have a bathroom or even a kitchen in it for easy living.

Step 1:Clarify Material Access Standards (Source Control)

Create a "qualification verification + sampling re-inspection" protocol. Set Num Researcher within range for import milestones materials like Q355B steel (yield strength ≥ 355MPa), EPS thermal insulation material (thermal conductivity ≤ 0.042W/ (m-K)) and door locks (tensile resistance ≥ 1000N) to control source quality.

Step 2:Steel Cutting and Blanking

Adopt CNC plasma cutting. Bring the dimen deviation≤±1mm; the cut edges’ verticality ≤0.5mm/m; no burr or missed corner are allowed. Pass 100% on cut-edges appearance inspection.

Step 3:Frame Welding

Use CO₂ gas shielded welding (cycles 120-180A, volts 20-25V). Weld height must be over six mm and jig is smooth and defect free. Ensure all the main frame welds ultra-sonic diagnosis where flaw proof. Re-weld non-conforming weld joints and recheck.

Step 4:Frame Straightening and Forming

Make sure that the skewness after straightening does not go above 3mm, the column bends less than 2mm / m, and the beam gets twisted less than 1 mm warp / m. This is a very important place of 100% exam and mag in powder testing to stop cracks and warpage.

Step 5:Enclosure System Installation (Core of Thermal Insulation and Waterproofing)

Use 1.8mm magnesium oxide boards on the ground with weld gap ≤ 200mm and without hollowing. Fulfill the splicing gap of EPS thermal insulation boards ≤ 2mm. Double use the overlap of external wall color steel plates ≥ 100mm, the roof slope ≥ 5° and take a; 24 hour water tightness test to prevent as for leakage.

Step 6:Supporting System Installation (Doors, Windows, Water and Electricity)

Follow the rule of standard barrier of doors and windows for the purpose of strict (air leakage ≤ 0.1m³/ (H·Tsquare) for 0.5kpa). Tempered glass shall be used when thickness is ≥ 5mn. For water and electric systerns lvert BV wire copper tail and PPR pipes shall be used. Do a water pressure test with pressure of 0.8MDia within 30mins with pressure drop ≤ 0,05 PMa. Pass the power on test at 100% rate.

Step 7:Factory Acceptance and Filing (Inspection Closure)

Perform the three-inspection system, (self-inspection, mutual inspection, special inspection). Slide tags on qualified box, take photo to save the file. Isolate and rework the unqualified products. Keep all the files more than 3 years.

Step 8:Delivery Acceptance Coordination

The validation officers will go with the customers for approval. If there are any objections, sign the validation form. Make a correction within 24 hours for any issues found and double check after the work is done.

Step 9:Quality Tracking and Feedback

Set particular all the right files and do follow-up as per plan "Month return after visit, 3 months to check, 1 year of care". Reply to the customer with problems within 48 hours and fix the problem within 72 hours. Reach the site within 24 hours if it is an emergency.

Cammi House has a very high 90,000-squaremeter factory to make things. It has very automated machines that can make containers and capsule homes fast and well. We are the big gest makers of such things in the world. We have the best tools and work such that our products are now faster and better. We will continue to give us the best over tme. |

| ✔ Flexible Delivery Time | ✔ Low MOQ | ✔ Exclusive Regional Rights & Pricing Support |

| Useful for storing goods and on time shipments | Create your own combination of products with a flex MOQ | Brand Authorization means a better hold on the market |

| ✔ High Cost-Effectiveness | ✔ Custom Logo | ✔ R&D Resources |

Propose sensible rates to boost overall value. | Custom Small Batch Logo for Personalisation | 3D sample pictures and Floor plans can be given in only 7 days |

| ✔ Wide Product Selection | ✔ One-Stop Marketing Package | ✔ 15 Days Fast Delivery |

| Options to satisfy demands of each section of market | Provide Nice Photos, Clips to Get More Cash from Sales | Get the Best Speed on the Thing Fastest, and Create It Well on within 15 Days. |

Products go through many technical tests likeCE FCC ETL.IS0 9001. and Eneray Star every year, based on what customers want to make sure they meet the safety, quality, and efficency rules of the use of product.

130+

Certifed Patent

Consider patent covers of all high tech so as to legalise and sustain on the market.

3000+

Project Cases

Provided labor on 3000+ jobs, this strength has created a faster way to build shipping container house.

10%

New R&D Expenses

Annually 10% of the profits are invested in constant bit-ups of the products.

100+

Technical Team

Full tech team will take care of both speed and quality.

Commercial Use

Motel& Resort

Mining Camp

Construction Camp

Thank you very much Cammi for the great camp solutions perfect for our needs; for example, the steel-structured factories, furniture and camp equipment for our pace capsule project, United States. We are really happy with the job they did and we are going to work with them again on other projects.

Cammi always gives us good quality products for the Space Capsule Thailand project! We have worked with them a total of 3 times. They are happy to help and they know what they are speaking about! I would strongly recommend Cammi to anyone who needs a prefabricated house.

Cammi planned, came up with the design of and drove our universe pod project in The Netherlands and Maryland. All this was done on our minute budget and on time. Our universe pod has been in use for two years now. The anti-corrosion drainage system works very well. We are very happy with the quality of the container.

Q: What kinds of products can you offer?

A: We have a wide range of houses including prefabricated K houses, prefabricated T houses, seaside houses, mobile cabins, light steel structure buildings, surveillance and more.

Q: What are your house materials?

A: The main stel structures are square tube "c" section stel H" section stel angle steel The walland roof materials are waterpro EPS panel fireprof frock wol panel Welinsulated PU panel Strong concrete panel These materials can be used for more than 30 years.

Q: Are you the factory or the trading company ?

A:Yes we are a factory and we could offer you a favorable price.

Q: Did you have the experience to cooperate with the government?

A: Yes,we have many ways to work with the government. We have worked with the Maldives Government,Inda Government, lndonesia Government,East TimolGovernment,Phllppines Government, Pakistan Government and many more.

Q: How is your after-sales service?

A:

1. If you have any questions, you are free to send us a message. We are on-dime all time for you.

2. For each order, one treatser will get one special person follow the whole production.

3. For the house and intergabge, we will give you the 3D instal drawing. If you like, we can send you an enginer to teach your workers, but request you to pay his return tirp, lodge, meal and salary.

Q: What information should we offer before you quote ?

A: If you have the drawing, please give and tell us the material you use.If you don't have the drawing, please tell us the size of the house. Then we design for you at a good price. Have any question, don't hesitate to contact us !!

Internet-famous Box

Double-opening Z case

Expansion Box

Packing Box

Mesaieed Industrial City 10,000-Man Workers Camp

August 1,2025/ August 20.2025

Cammi ran life support camp for 10,000-capacity plant and liquid/oil storage at Qatalum to work for.

Worker Residential Cityfor 26.000 Man

November 18,2025/ November 25.2025

Any ready and cutting Cammi finished the job on 26,000 work men city project.

Mobile Medical Hospital and First AidStations

December 1,2025/ December 3.2025

British residents can enjoy Cammi's health clinics in just 120 minutes as they have been made readily accessible through extensive research and development.

Product Highlights 1. Detachable Modular Design – Make it easy to move, build fast, and move on. 2. Strong Steel Structure – One that’s steady, lasts a long time, and strong. 3. Fast Installation – Prefabs cut labor and time. 4. Best for Dorms, lines of work — great for workers’ rooms, and short stays.

Product Highlights 1. Detachable Design – Simple to carry, build, and move. 2. Small Single Office Layout – Small space for on-site or no-longer work spaces. 3. Sturdy Steel Structure – Robust, safe, and tough for every day use. 4. Fast Setup – Prefab system cuts down on time and work.

Product Highlights 1. Pre-made container house system – Built to high standards with good function. 2. Removable Frame Design – Simple to put together, take down, and move. 3. Fast Container House Style – Well separated parts with a newer look. 4. Multi container homes solution – For flat out living, working or short-term use.