| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

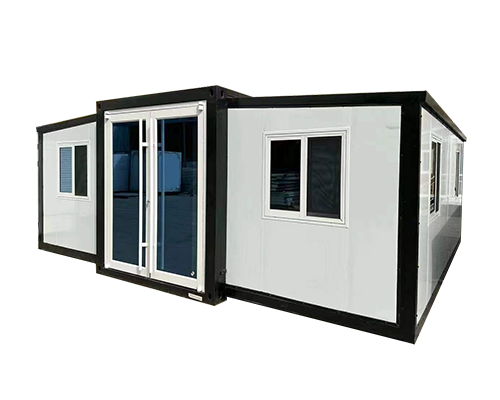

WHAT IS THE DETACHABLE CONTAINER HOUSE

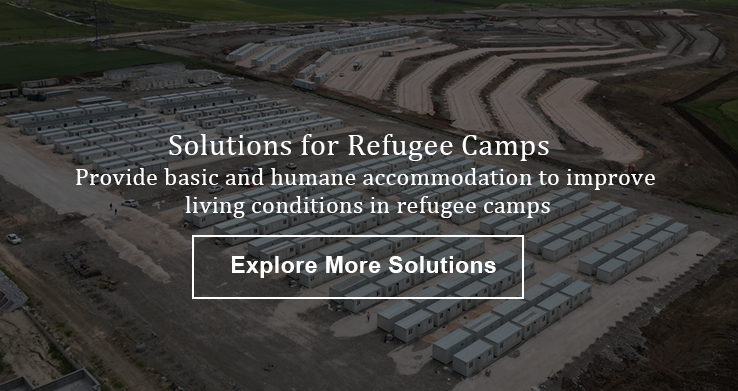

Prefabricated detachable container houses are a type of dwelling form constructed by prefabbing separate parts in a factory and travelling to the Jobsite in order to be assembled into one house. They are cheap, more earth friendly and flexible to adapt. These dwellings are actually normally slated to be some editability and take away on the back of steel that can survive any matter weather and please practical and social vehicle conditions. This they are great for residential building.

DETACHABLE CONTAINER HOUSE STRUCTURE

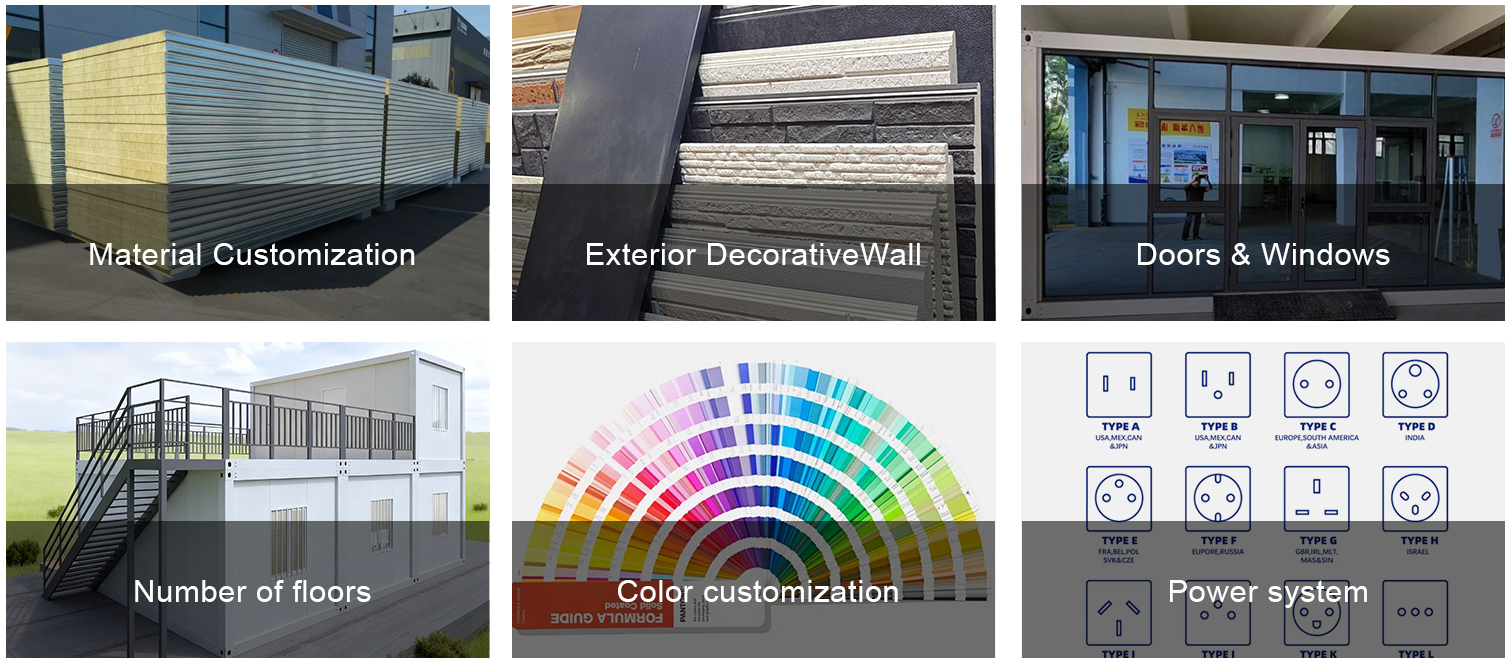

Detachable container size are normally 3*6 meter(20 feet), have one door, two windows and everything else such as electric and light that a normal house would. The 20 foot container house is very portable. The aesthetic of the container house can be designed to your best liking in terms of its size, the thickness of the shell, and its shell composition. Its interior can be added with many functions as needed and a bathroom or kitchen can be added to allow more with the home.

Step 1:Clarify Material Access Standards (Source Control)

Create a "sample check + source quality check" system. Make needed rules for raw materials. Some examples are Q355B steel (high stress strength ≥ 355MPa), EPS type ins. (heat stretch formatter ≤ 0.042W/(m·K)), and the lock for the gateway (pull high stake≥ 1000N). These rules will help in having baseline quality.

Step 2:Steel Cutting and Blanking

Purchase CNC plasma cutting. Make sure the content error is within ±1 mm, the cutting edge angle is within 0.5mm/m and there are no burrs or corners missing. SEO both the litter of the cutting edges statues.

Step 3:Frame Welding

Use CO₂ gas shielded welding (Amperage: 120-180A, Voltage: 20-25V). Weld height must be ≥6mm and defect free. Main frame weld shall be tested 100% with ultrasonic flaw detector. Welds passed the test shall be reworked and re-inspected.

Step 4:Frame Straightening and Forming

Once kept straight, make sure the long/side gradient no greater than 3mm, a thumbs width out of line in any direction, and the the beam is longer than flat 1mm/m. Carry out 100% check and magnetic particle checking for important parts to make sure no crack or deformation.

Step 5:Enclosure System Installation (Core of Thermal Insulation and Waterproofing)

Replace the floors with 1.8mm magnesium oxide boards with weld spacing≤200mm and no hollowing. The splicing gap of EPS thermal insulation boards should be no more than 2mm. The external wall color steel plates should be overlapped by at least 100mm, the roof slope should be no less than 5°, followed by a 24h watertightness test to prevent any leaks.

Step 6:Supporting System Installation (Doors, Windows, Water and Electricity)

Guarantee air tight on doors and windows as per standard: air leak≤0.1m³(/h ・㎡) at 0.5kPa, Use hardness glass≥5mm, Use BV copper core wires and PPR pipes appertaining to the water and electric system, carry out the water pressure test at 0.8MPa for 30min with pressure loss≤0.05MPa, Power on test should get 100% pass rate.

Step 7:Factory Acceptance and Filing (Inspection Closure)

Implement three-inspection system: self inspection, mutual inspection, special inspection. Labels attached to qualified cabins and photos taken for record. Unqualified products isolated and reworked. All records stored more than 3 years.

Step 8:Delivery Acceptance Coordination

Customers are taken by quality control personnel for acceptance. If no complaints are received, sign confirmation and if received on the signing, if problems are found, the Quality Control personnel will draw up a correction plan within 24 hours and re-inspect after rectification.

Step 9:Quality Tracking and Feedback

Set up special quality documents and do a follow-up to follow the '1-month re-visit, 3-month check, 1-year service' plan. Reply to customers' problems in 48 hours and fix within 72 hours. Come to the site within 24 hours for emergency problems.

Cammi House has a top-notch 90,000-square-meter factory that makes all kinds of things. It has fully automatic processes. It is the world’s biggest place for making containers and capsule homes. We use the newest technology and quick methods to make the best things at a fast pace. Our high level of quality makes us leading the way. We push the limits on innovation and keep the environment clean through modular building. |

| ✔ Flexible Delivery Time | ✔ Low MOQ | ✔ Exclusive Regional Rights & Pricing Support |

| Timely delivery plans and warehousing help | Flexible MOQ with mixed product options | Brand Authorization Gives a Win to the Company in the Business World |

| ✔ High Cost-Effectiveness | ✔ Custom Logo | ✔ R&D Resources |

Offer prices that are competitive so as to get the biggest benefit. | Custom Logo Personalization of Small Quantity | Give 3D empty pictures and blue prints in 7 days |

| ✔ Wide Product Selection | ✔ One-Stop Marketing Package | ✔ 15 Days Fast Delivery |

| Alternate ways to satisfy all kinds of customers | Give High-quality Pictures, Clips To Improve Sale Income | Fastest When It Comes to Making and Shipping in 15 Days. |

Products are subject to so many different technical certifications and testing like: CE, FCC, ETL, IS0 9001. and Energy Star ever

year to customer specifications and meet worldwide safety, quality and smart standards.

130+

Certifed Patent

Investigate the patent to make sure your products are protected and you stay on top of other competitors on the market.

3000+

Project Cases

We have done more than 3,000 projects and that gave us a way to assemble containers in a wise way.

10%

New R&D Expenses

Annual 10% of sales are spent on the making better products, all the time.

100+

Technical Team

When you use the full tech team , you have both excellent quality and service.

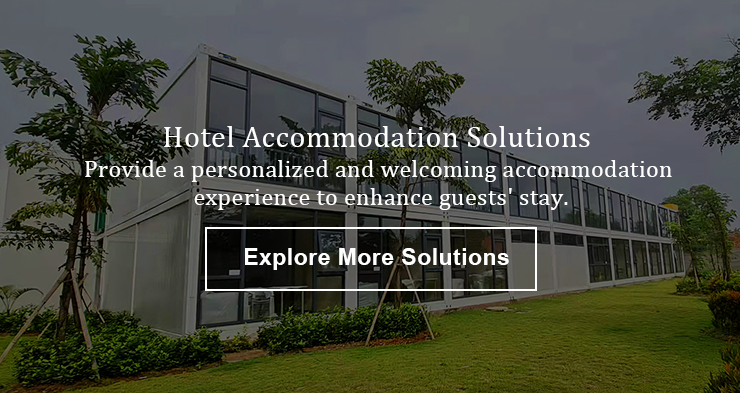

Commercial Use

Motel& Resort

Mining Camp

Construction Camp

Please help us thank Cammi for giving us good camping help—steel-built plants, furnishings, and camp gear for our pace capsule project in the Western World. We are happy with what they did and hope to work with them again soon.

Cammi is our best supplier for the project of Space Capsule Thailand. We have worked with them three times in a row. l really like their friendly and professional team! l will always recommend Cammi to any one looking for a good prefabricated resident.

Our space pod project in Rheinl and Bay was made, built, and helped with by Cammi. The whole project was within our small budget, and it was done on time. The space pod has been working for two years. The anti-corr drain system is superb. We are very happy with the container's quality.

Q: What kinds of products can you offer?

A: There's many types of buildings that include types of K house and T house, villas, transportables, light steel buildings and sheers, and much more.

Q: What are your house materials?

A: CHief of main stel structures is square tube,"c" section stel,"H" section stel, angle steel. Walland roof materials are waterpro EPS panel; fireprof frock wol panel; Welinsulated PU panel; Strong concrete panel, These materials can be use for more than 30 years.

Q: Are you the factory or the trading company ?

A:Sure, we are a factory and we can give you a good price.

Q: Did you have the experience to cooperate with the government?

A: Yes, we have a lot of past work with other governments. We have worked with the Government of the Maldives, the Government of India, the Government of Indonesia, the Government of East Timor, the Government of the Philippines, the Government of Pakistan, and the list goes on.

Q: How is your after-sales service?

A:

1. Any questions, welcome to contact us, 24 hours are in your hand. One order, one special person follow you all through the production.

2. For the house install.tion, we will give you the 3D install drawing. If you need, can send you an engineer to teach your workers.

3. But you have to charge the return ticket, the room, food and salary.

Q: What information should we offer before you quote ?

A: If you have the blue print, plz give us and tell us the material you using. If you don't have the blue print, plz tell us the size of the house. Then we having make design for you with good price. any question, don't worry conact us!!

Internet-famous Box

Double-opening Z case

Expansion Box

Packing Box

Mesaieed Industrial City 10,000-Man Workers Camp

August 1,2025/ August 20.2025

Cammi ran life support camp for 10,000-capacity plant and liquid/oil storage at Qatalum to work for.

November 18,2025/ November 25.2025

Any ready and cutting Cammi finished the job on 26,000 work men city project.

Mobile Medical Hospital and First AidStations

December 1,2025/ December 3.2025

British residents can enjoy Cammi's health clinics in just 120 minutes as they have been made readily accessible through extensive research and development.

Product Highlights 1. Detachable Modular Design – Make it easy to move, build fast, and move on. 2. Strong Steel Structure – One that’s steady, lasts a long time, and strong. 3. Fast Installation – Prefabs cut labor and time. 4. Best for Dorms, lines of work — great for workers’ rooms, and short stays.

Product Highlights 1. Detachable Modular Design – Can be transported easily, assembled fast, and moved around as needed. 2. Hospital-Ready Layout – Made for use in hospitals, isolation rooms, and short-term clinics. 3. Strong Steel Structure – Sturdy, dependable, and able to run for a long time. 4. Rapid Deployment – Modular system, so setting up can be fast in an emergency case.

Product Highlights 1. Pre-made container house system – Built to high standards with good function. 2. Removable Frame Design – Simple to put together, take down, and move. 3. Fast Container House Style – Well separated parts with a newer look. 4. Multi container homes solution – For flat out living, working or short-term use.