| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

WHAT IS THE MIC BUILDING

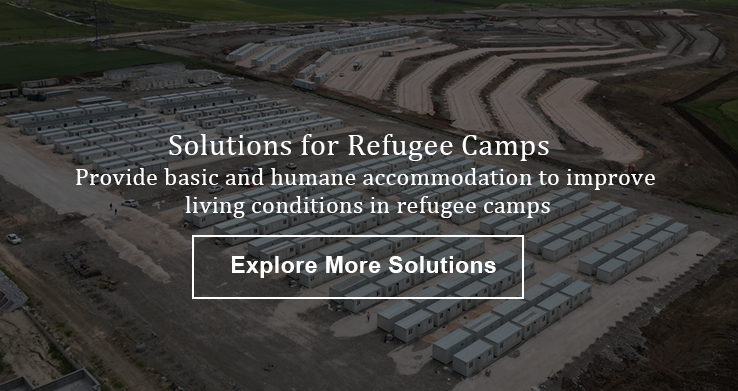

Modular integrated building containers are small ready-made parts gifted. They give strength, fast increasing on location (ready for usage just after fixing), and changeable way they serve as a cheap and eco-friendly whole building pack to temporary lodging, trade outlets, and civic network places.

MIC BUILDING STRUCTURE

The product structure of an MIBC is a layered, factory-built combination system. Its heart is a load bearing (main) steel frame, a high quality complete building cover with insulated wall/roof panels (often sanchiron build) and a fully joined in side. within this assembled finish are already fixed MEP systemsstay in the walls and working fixtures. All parts are made to dead accurate always, with standard, hidden attachment points for fast installation on-site work and utility hookup.

Modular Integrated Construction Container Project

Size: 5800(L)mm * 2480(W)mm * 2560(H)mm

Weight:1400kg

40HQ=10 units

Step 1:Clarify Material Access Standards (Source Control)

Create a “qualification review + sampling re-inspection” system. Create numbers for some main parts such as Q355B steel (strength at break ≥ 355MPa), EPS live material (warmth conduct at break ≤ 0.042W/(m·K)), and latch (key advantage at break ≥ 1000N) so that you can control the source of quality.

Step 2:Steel Cutting and Blanking

Use CNC plasma cutting. Make sure the difference in size is less than or equal to ±1mm, the angle of the cut edge is less than or equal to 0.5mm/m, and there are no burrs or corners are lost. Check the appearance of all cut edges.

Step 3:Frame Welding

Adopt CO₂ gas shielded welding (Input: 120-180A, 20-25V). Make sure the weld height≥6mm and there are no flaws. 100% ultrasonic flaw detection shall be carried out on the main frame welds. Rework those unqualified ones and re-inspect them.

Step 4:Frame Straightening and Forming

Ensure the diagonal deviation after straightening ac ≤ 3mm, the column top and bottom slope error ac ≤ 2mm/m, and the flatness of the beam ac ≤ 1mm/m; adopt 100% inspection and magnetic powder test to the key parts and dock to no conflict or deformation.

Step 5:Enclosure System Installation (Core of Thermal Insulation and Waterproofing)

Use 1.8mm magnesium oxide boards for the floor with weld spacing ≤ 200mm and no hollowing. Make sure the splicing gap of EPS thermal insulation boards ≤ 2mm. The overlap of external wall color steel plates ≥ 100mm, the roof slope ≥ 5°, and do a 24-hour water tightness test to avoid leakage.

Step 6:Supporting System Installation (Doors, Windows, Water and Electricity)

Check that the air tightness of door and window satisfies the standard (air leakage rate ≤ 0.1m³/(h·㎡) under 0.5kPa). Use tempered glass≥5mm thick glass. Adopt BV copper core wires and PPR pipes for water supply and the electricity system. Perform water pressure test at 0.8MPa for 30 minutes with pressure drop≤0.05MPa. Power-on test shall pass rate of 100% pass rate.

Step 7:Factory Acceptance and Filing (Inspection Closure)

Follow the three checks system (see yourself, share with others and check with last person). Stick tags on all the good cabins and take a shots for file. Remove and fix bad products. Preserve all the papers for over 3 years.

Step 8:Delivery Acceptance Coordination

CUSTOMERS are accompanied by Q.C. personnel and take their acceptance. Sign the acknowledgement form if no complain. Take correction plan within 24 hours if problem happening, and re- inspection after rectification.

Step 9:Quality Tracking and Feedback

According to the "1-month return visit, 3-month inspection, 1-year maintenance" plan, develop only high-quality files, and do follow-ups. In response to customer issues, act within 48 hours and fix them within 72 hours. For emergency problems, go to the place within 24 hours.

Cammi House has a modern factory that covers 90,000 square meters. It has professionally made production lines. The factory produces capsules and container homes the world's largest manufacturing plant. We use the latest technology and efficient procedures to make the best quality products fast. Cammi House leads the way by setting standards, and pushing for new ways to build modular homes. |

| ✔ Flexible Delivery Time | ✔ Low MOQ | ✔ Exclusive Regional Rights & Pricing Support |

| Reliable delivery schedules and warehousing support | Flexible MOQ with mixed product options | Brand Authorization Ensures a Competitive Edge in the Market |

| ✔ High Cost-Effectiveness | ✔ Custom Logo | ✔ R&D Resources |

Competitive pricing to maximize overall value. | Personalized Logo Customization for Small Batches | Provide 3D Sample Images and Floor Plans Within 7 Days |

| ✔ Wide Product Selection | ✔ One-Stop Marketing Package | ✔ 15 Days Fast Delivery |

| Diverse Options to Cater to All Market Segments | Provide Quality Images, Videos to Enhance Sales Revenue | Efficient Production and Ship Within 15 Days at the Fastest. |

Products go through many tests and certifications each year based on what customers want to make sure that they are safe,

of good quality and work well. These include CE FCC ETL.IS0 9001 and Eneray Star.

130+

Certifed Patent

Make sure each technology has its own patent so that it is protected by law and you stay the only one in your field.

3000+

Project Cases

Completed more than 3,000 projects thou strength learnt how to build a fast and less wasteful form of aroune ships.

10%

New R&D Expenses

10% of profit is spent every year on made better ever-lasting the products.

100+

Technical Team

Only a full expert team makeup, could be sure of good que and good service.

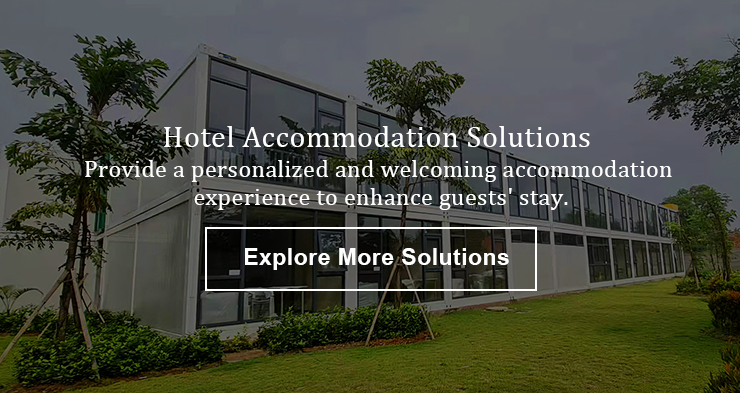

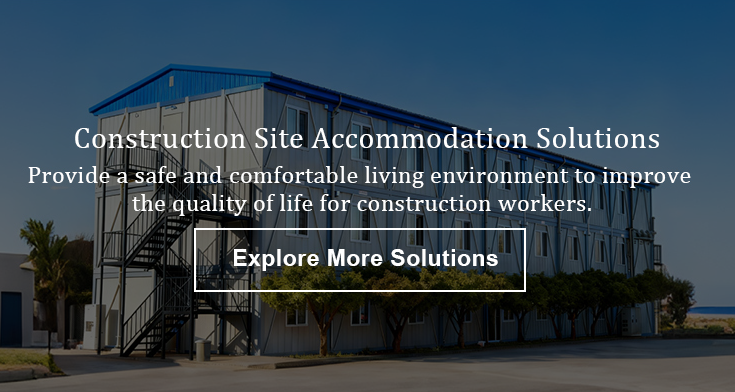

Commercial Use

Motel& Resort

Mining Camp

Construction Camp

We thank Cammi for providing us with perfect camp solutions, including steel-structured factories, furniture, and camp equipment for our pace capsule project in the United States. We are very satisfied with their efforts and achievements and look forward to working with them again on future projects.

Cammi is our reliable supplier for the Space Capsule Thailand project. We have worked together three times in a row. l love their friendly and professional team! l highly recommend Cammi to anyone looking for high-quality prefabricated houses.

Our space pod project in Rheinl and Bay was designed, manufactured, and supervised by Cammi. The entire project met our low-cost budget and delivered on time. The space pod has been in operation for two years. The anti-corrosion drainage system is excellent. We are very satisfied with the quality of the container.

Q: What kinds of products can you offer?

A: We ofer a series of houses, such as prefabricated K house, prefabricated T houses, vila, mobile containers, light steel structure buildings, guard and so on.

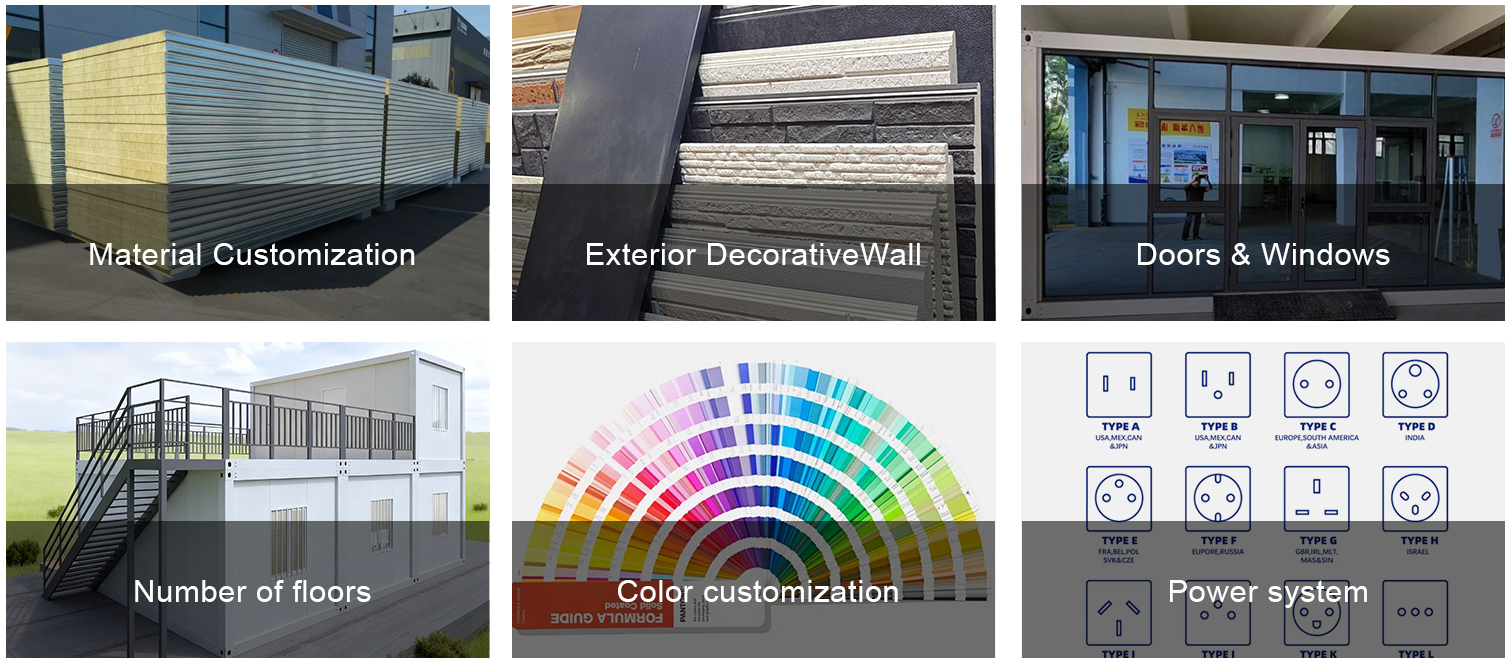

Q: What are your house materials?

A: The main stel structures are square tube,"c" section stel,"H" section stel, angle steel. The walland roof materials are waterpro EPS panel; fireprof frock wol panel; Welinsulated PU panel; Strong concrete panel, These materials can be used for more than 30 years.

Q: Are you the factory or the trading company ?

A: Certainly, we are a factory and we can offer you a good price.

Q: Did you have the experience to cooperate with the government?

A: Well,we have many experiencesto cooperate with the government. We have cooperated with the Maldives Government,Inda Government,lndonesia Government,East TimolGovernment, Philippines Government, Pakistan Government and so on.

Q: How is your after-sales service?

A: 1. Any questions, welcome to contact us. 24 hours are available for you.

2. One order, one special person to follow the whole production.

3. Forthe house installation, we willprovide you the 3D instal drawing. lf you need, we can send you an enginer to teach your workers, but you have to charge the return ticketaccommodation, food and salary.

Q: What information should we offer before you quote ?

A: If you have the drawing, please give and tell us the material you use.If you don't have the drawing, please tell us the size of the house. Then we design for you at a good price. Have any question, don't hesitate to contact us !!

Internet-famous Box

Double-opening Z case

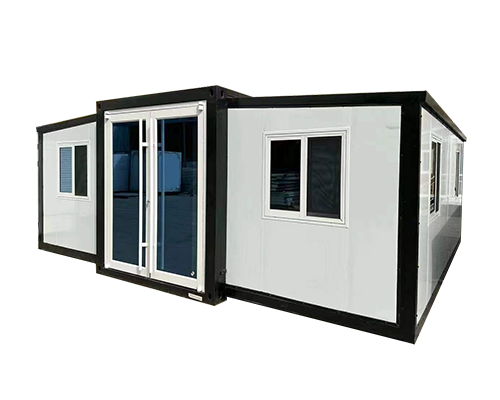

Expansion Box

Packing Box

Mesaieed Industrial City 10,000-Man Workers Camp

August 1,2025/ August 20.2025

Cammi ran life support camp for 10,000-capacity plant and liquid/oil storage at Qatalum to work for.

November 18,2025/ November 25.2025

Any ready and cutting Cammi finished the job on 26,000 work men city project.

Mobile Medical Hospital and First AidStations

December 1,2025/ December 3.2025

British residents can enjoy Cammi's health clinics in just 120 minutes as they have been made readily accessible through extensive research and development.