Introduction

Container houses have moved far beyond their early image as improvised or experimental shelters. By 2026, they have become a standardized construction system used by governments, NGOs, industrial developers, and private investors across multiple regions. What defines a container house today is not the reuse of a shipping container, but the adoption of a modular, transportable, and factory-controlled building logic.

1. What Is a Container House?

A container house is a modular building unit designed for human occupation, manufactured off-site, and transported in standardized dimensions for rapid assembly. Unlike traditional construction, which relies on sequential on-site processes, container housing follows a productized construction logic, where structural systems, insulation, MEP components, and finishes are pre-integrated under controlled factory conditions.

The key distinction is that modern container houses are not repurposed cargo containers. They are engineered modules that borrow dimensional logic from ISO containers for logistical compatibility, while being structurally optimized for habitation. This approach enables predictability in quality, speed of deployment, and cost management—three factors that increasingly define construction feasibility in large-scale projects.

2. Why Container Houses Matter in 2026

The relevance of container houses is driven by systemic pressures on the global construction industry. Urban population growth, climate-related displacement, labor shortages, and rising material volatility have made traditional building methods less predictable. In this context, container housing systems offer a way to shift risk from the construction site to the factory, where quality, timelines, and costs can be controlled.

From a project management perspective, the value of container houses lies not only in speed, but in risk compression. Procurement teams can lock specifications early, logistics can be planned in advance, and installation becomes a controlled operation rather than a variable-dependent process. This predictability is often more important than nominal unit cost.

3. Types and Classification of Container Houses

Container houses should not be treated as a single product category. They form a spectrum of systems with different performance levels, lifespans, and deployment logics.

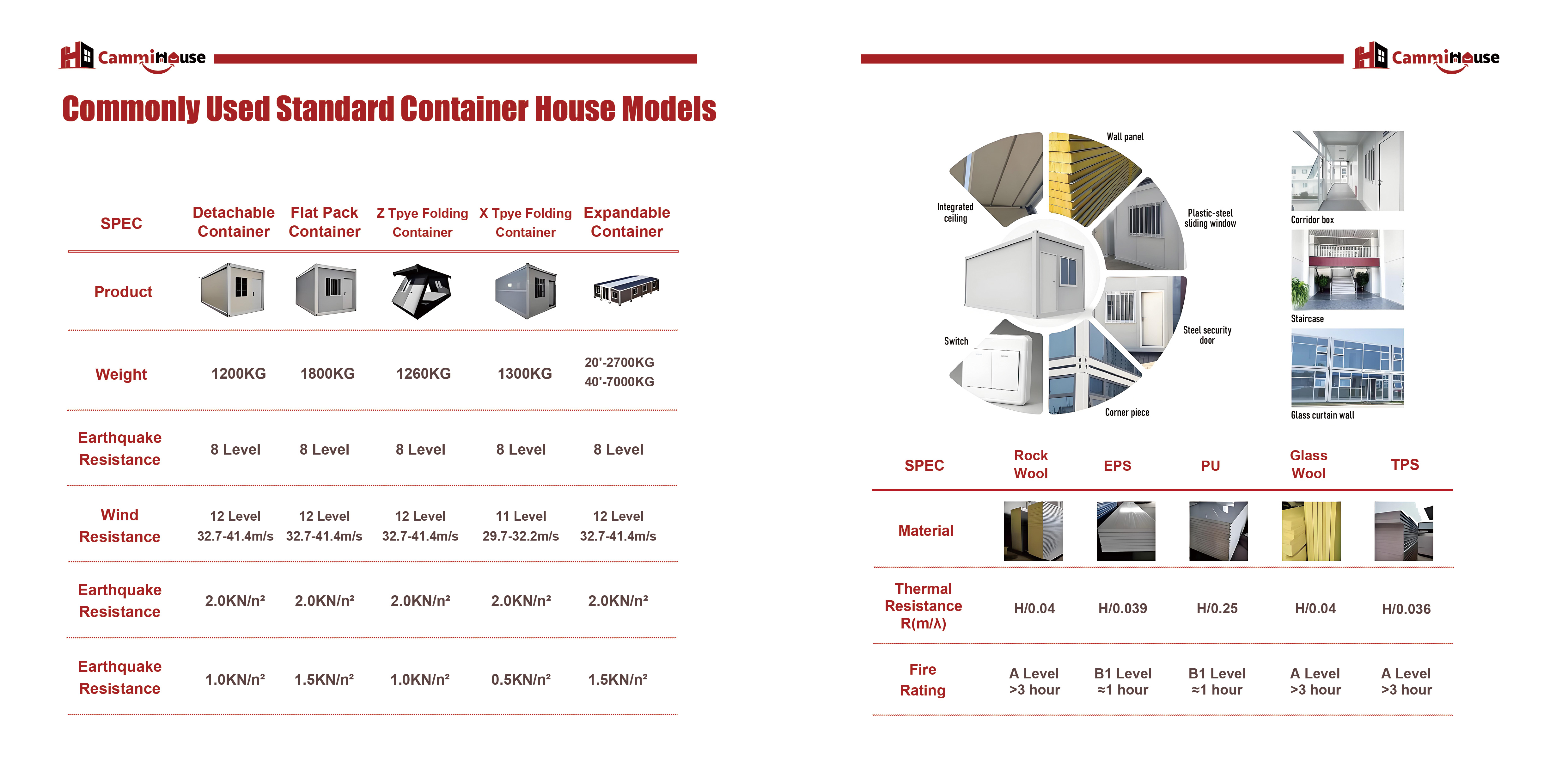

3.1 Flat-Pack Container Systems

Flat-pack systems are shipped disassembled and assembled on-site. They minimize shipping volume, making them suitable for remote regions or high-tariff markets. However, they require more on-site labor and quality control.

3.2 Foldable Container Units

Foldable systems collapse into compact transport volumes and expand on-site. They are optimized for speed and emergency response scenarios.

3.3 Expandable Container House

These systems use expandable structural sections that extend outward to increase interior space. They offer flexible layouts and better long-term usability.

3.4 Detachable Container House

They make use of removable structural parts that can be set up or taken apart as required. They allow for flexible set up and better repeat use over time.

3.5 Modular Stackable Units

These systems use rigid volumetric modules that can be stacked or connected horizontally. They provide better insulation performance and long-term durability.

4. Core Use Cases

4.1 Construction Worker Camps

Scalable housing systems with predictable deployment timelines.

4.2 Disaster Relief and Emergency Housing

Rapid deployment, low logistics volume, and quick habitability are essential.

4.3 Government and Public Housing

Long-term systems focus on durability, code compliance, and lifecycle cost.

4.4 Commercial and Mixed-Use Buildings

Container systems enable fast market entry and relocation flexibility.

5. Procurement and Selection Logic

Choosing the right container housing system is a multi-variable decision. Factors such as climate, regulatory environment, labor availability, and long-term maintenance must be evaluated.

A low unit price does not necessarily indicate a low project cost. Foundations, utilities, compliance adaptations, and replacement cycles often dominate lifecycle expenses.

6. Risks and Misconceptions

Container houses are not universal solutions. They are often misapplied to projects that require high architectural flexibility or where logistics infrastructure is weak.

Overemphasis on speed can lead to under-specification, especially in insulation and moisture control.

7. FAQ

Q1: Are container houses permanent buildings?

Yes, if engineered for permanence. Structural system, insulation, and foundation design determine lifespan.

Q2: How long does installation take?

From hours (single unit) to weeks (large deployments), depending on scale.

Q3: Do container houses meet building codes?

They can, but must be engineered for local regulatory frameworks.

Conclusion

Container houses represent a shift in how buildings are designed, produced, and deployed. Their value lies not in novelty, but in predictability, scalability, and controlled quality. When applied correctly, they offer a viable alternative to traditional construction.

For a deeper breakdown of container house types, see our in-depth comparison guide. If you want to explore performance in extreme climates, refer to our specialized article.